Chronicle tells the origin of Ready Access Closures in Brazil

By Joaquim Fanton*

When I began working for Telebrás, the engineering division operated on the first floor of the Ambassador Building, in a small office, comprised by a room and a bathroom. The room had six tables and one clipboard. Luckily, the bathroom had a shower box. At the time, there were no personal computers. We used to write notes and memorandums. In special cases, the secretary of the division would type them up. The documents were stored in files that were in the bathroom.

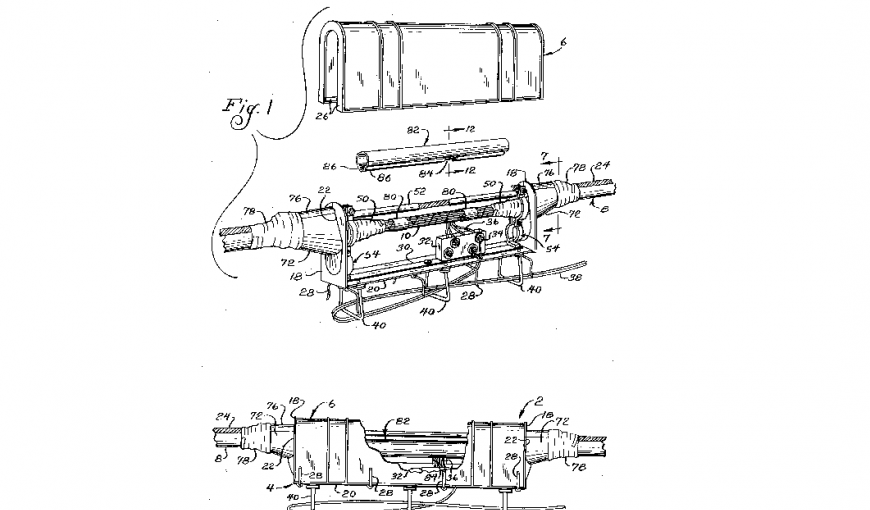

One afternoon, the phone rang. General Alencastro wanted to talk to me. Between me and him, there were two intermediate levels, but the organization of the time followed Army standards, upon which the superior officer speaks directly to any subordinate, at any time. I climbed up the stairs in a rush. The president handed me a splice closure. It was being used in the external network of a company in the countryside of São Paulo, recently bought by Telebrás. The manufacturer, a friend of the minister, wanted the closure to be analyzed, to be adopted in the Telebrás system.

A year before that, while I worked for Telesp (telecommunications operator in São Paulo), I stayed in the United States for twelve weeks. During that period, I became aware of products and construction practices used in the American networks. I was in California, Virginia, New York and Ohio. In the end, I brought designs, specifications, handbooks and samplings of various materials. During my stay in Chicago, I visited Cook Electric in Morton Grove and Reliable in Franklin Park, companies that manufactured network accessories. A splice closure similar to that in the picture also came with me.

One of the first measures that I took in Telebrás was to create a working group to develop a Brazilian Ready Access Closure. The group featured representatives from various providers. The technical coordination was by engineer Rosa Cruz Ferreira, who worked in Telerj’s (telecommunications operator in Rio de Janeiro) Development Laboratory, a highly skilled professional.

On the day I received the closure from General Alencastro’s hands, the group was almost finishing the works. I knew every important point in the project: fastenings, anchors, electrical bonding, closures, holes for fastening terminal block, cable entries, entries for drop wires, anti-retraction clamp, etc. I inspected the closure and I concluded that, in order for it to be used, it needed approximately tem improvements. Then, I told them to put the closure in the shower box in the bathroom, obviously.

Days later, late afternoon, I was visited by the businessman, accompanied by two sons, one of them a recently graduated engineer. I grabbed the closure in the bathroom and opened it on my table. The visitors sat in front of me, all tight. In a didactic manner, I listed, one by one, the details to be included. After finishing each topic, the visitors expressed themselves, confirming they had understood, and one of them took notes about what should be done in a small notebook. The meeting lasted for over an hour. In the end, a deadline was established for them to bring me a new, modified sample. It was then that I took from the drawer the design of Telerj’s VSC, an improved copy of the closure brought from the US. I commented that the project foresaw every detail we had listed and I suggested that they took the drawing and arranged a comparative study of both closures. I made it clear that they had the freedom to proceed with their closure, as long as it was modified to meet our specifications.

Then, one of them remembered another commitment. A dinner with the minister. Saying our goodbyes, the three of them thanked me a lot! In the next morning, the phone rang. It was the technical director, who asked me to go to his room urgently.

- Fanton, what did you do last night? The minister called the general, who called me. The businessman you met yesterday said a brat hired by Telebrás threw his closure in the toilet! The minister ordered me to fire you.

With the splice under my arm and the technical director by my side, I went to the president’s room. I listed every point addressed in the beginning of the previous night. When I finished, the general phoned the minister.

- The complaint is ungrounded, the “brat” we brought from São Paulo is absolutely right. The man’s closure is unusable!

I do not know if a subsequent conversation between the minister and the businessman took place, but I believe it did. The fact is he decided to make our VSC.

Once under production, it quickly gained market share. As time went by, other manufacturers appeared and the product underwent some updates.

Many years later, I met the businessman’s engineer son in an event promoted by my division at a northeastern capital. We met at night, at a beach brewery. We drank some beers, and after a while, lips loose due to alcoholic effluvia, he admitted:

- Fanton, you are a nice guy and we wanted to harm you. We told the minister you threw our closure in the toilet. You should have! Ours was really crap.

Forty years later, the Ready Access Closure is still under use. A true phenomenon!

To confirm, just type “Ready Access Closure” into Google. Tens of offers and manufacturers will appear. Of course, countless alternatives appeared in the market. Some brought by international providers that arrived with the privatization. But they are more sophisticated and, consequently, more expensive. They are used because a certain client so decided.

In my opinion, the Ready Access Closure shall remain under use as long as a metal overhead wire exists.

Before I forget, in my trip to the USA in 1973, a white-haired manager taught me a Golden rule. When someone offers you a technological novelty, ask two questions: is it better? Is it cheaper?

Two positive answers: adopt the product fearlessly. A single no: forget about the subject and keep what you have!

*Joaquim Fanton is an electrical engineer from the Federal University of Paraná (UFPR), with 38 years of experience in optical networks. He was a network engineer of Paraná Telecommunications Company (Telepar) of Telecomunicações São Paulo (Telesp), Telebras and the Research and Development Center in Telecommunications (CPqD). Today, he acts as RNP consultant and participates in the implementation of metropolitan fiber optic networks, under the Digital Cities Programme. By walking through the countryside, he accumulated stories that will be shared on this website.[[{"fid":"6621","view_mode":"default","fields":{"format":"default","field_file_image_alt_text[und][0][value]":"Fanton","field_file_image_title_text[und][0][value]":"Fanton"},"type":"media","link_text":null,"attributes":{"alt":"Fanton","title":"Fanton","height":653,"width":641,"style":"width: 100px; height: 102px; float: right;","class":"media-element file-default"}}]]